All wheels strike a balance between aerodynamics (for higher speeds), weight (for climbing and acceleration), and compliance (for comfort and control).

The rim design philosophy focuses on maximizing performance across all areas, blending aerodynamics, weight optimization, and reliability to deliver the best possible wheel experience. However, to optimize performance for specific needs, wheels are tailored to different uses.

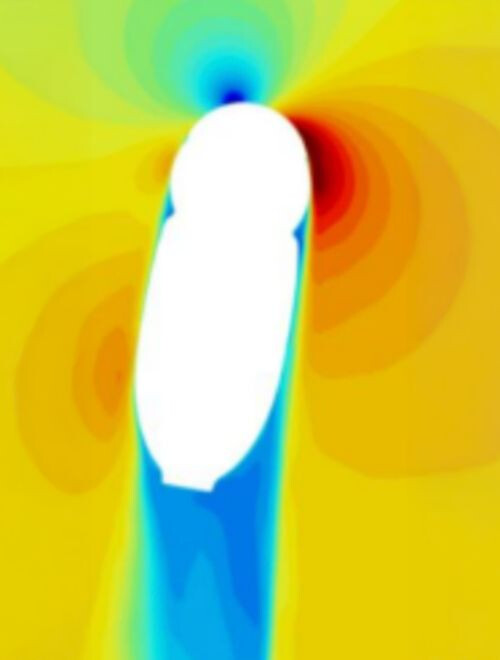

AERODYNAMIC PERFORMANCE

All rims are designed with aerodynamics in mind. However, the rims in the RA series place more emphasis on the ultimate efficiency at higher speeds. Designs like the mini hook reduce turbulence, and the rim designs are optimized in the wind tunnel to reduce drag and also to create designs which improve stability in crosswinds.

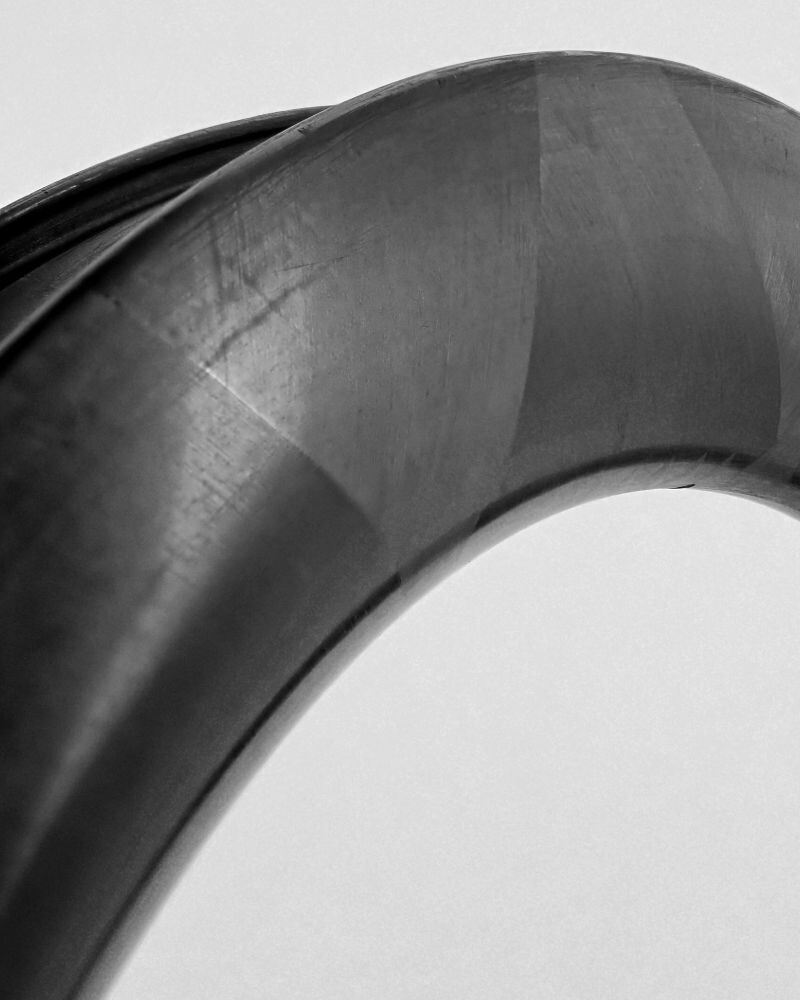

WEIGHT OPTIMIZATION

Weight is always crucial for wheels, especially at lower speeds, like on climbs, where weight plays a bigger role than aerodynamics. Along with using high-quality, lightweight materials, the rim designs incorporate features that reduce stresses, resulting in stronger and lighter rims.

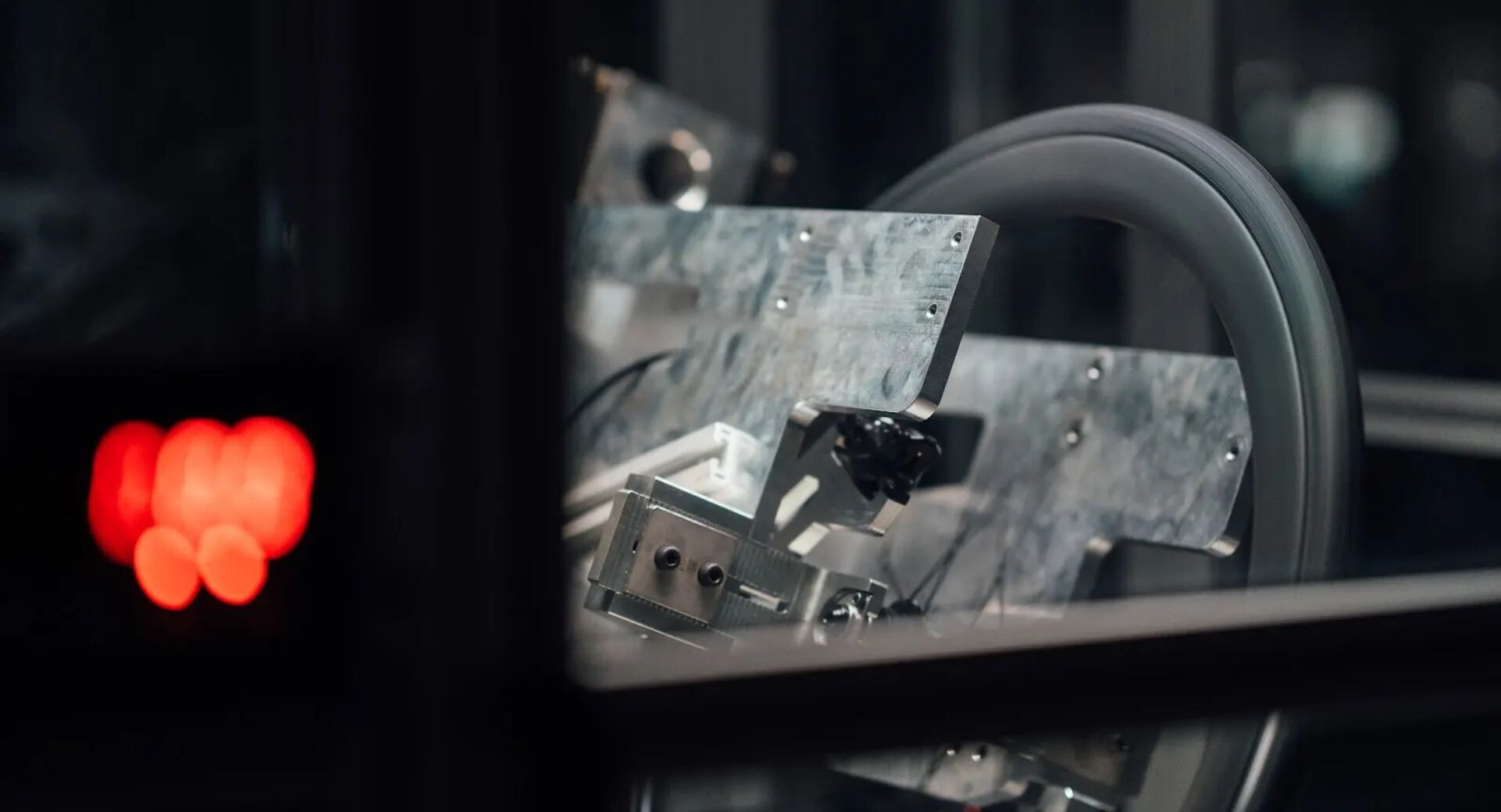

RELIABILITY AND DURABILITY

Precision engineering, high-quality materials, and smart design ensure a long-lasting, reliable wheel. The rims are built to endure tough conditions while maintaining consistent performance over time. The wheels are rigorously tested, both in the laboratory and in the real world, working with our professional teams and in-house testers to push them to the extreme, ensuring they meet the highest standards of performance and durability.

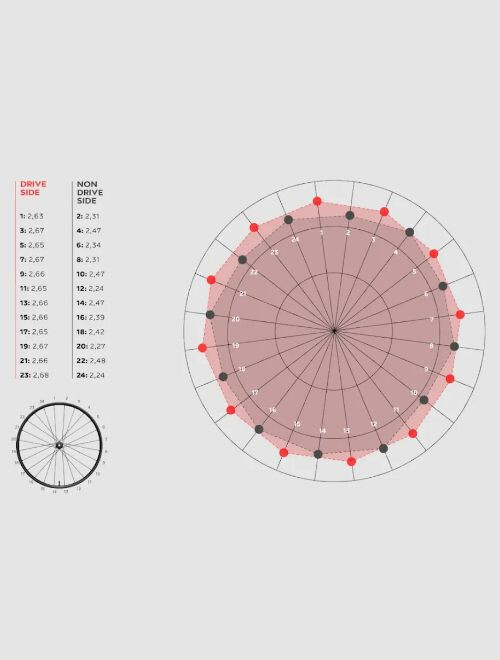

OVERALL DESIGN INTEGRATION

From the beginning of the design process, we consider the entire system of wheel performance. The combination of aerodynamics, weight optimization, and reliable construction makes our rims the perfect choice for high-performance riding across various terrains.