Perfection Takes Time

The best wheels come from the best components. Turning those parts into the perfect wheel is an art mastered by only a few. The performance and reliability of our wheels start with our facilities and manufacturing processes.

Watch video

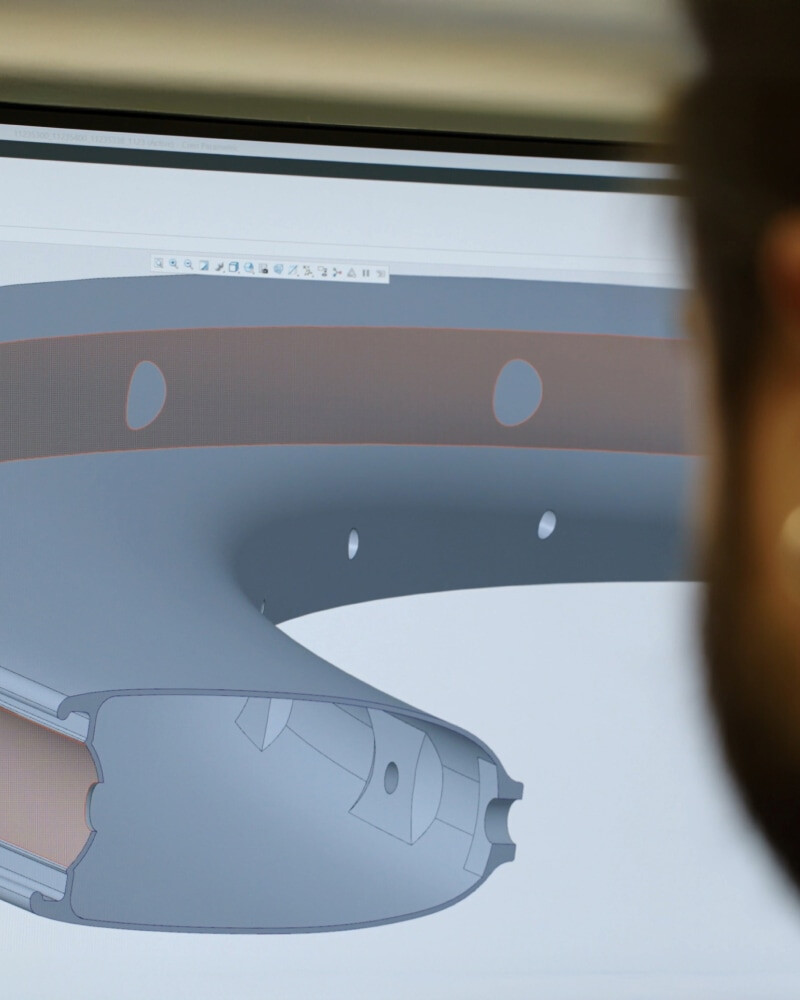

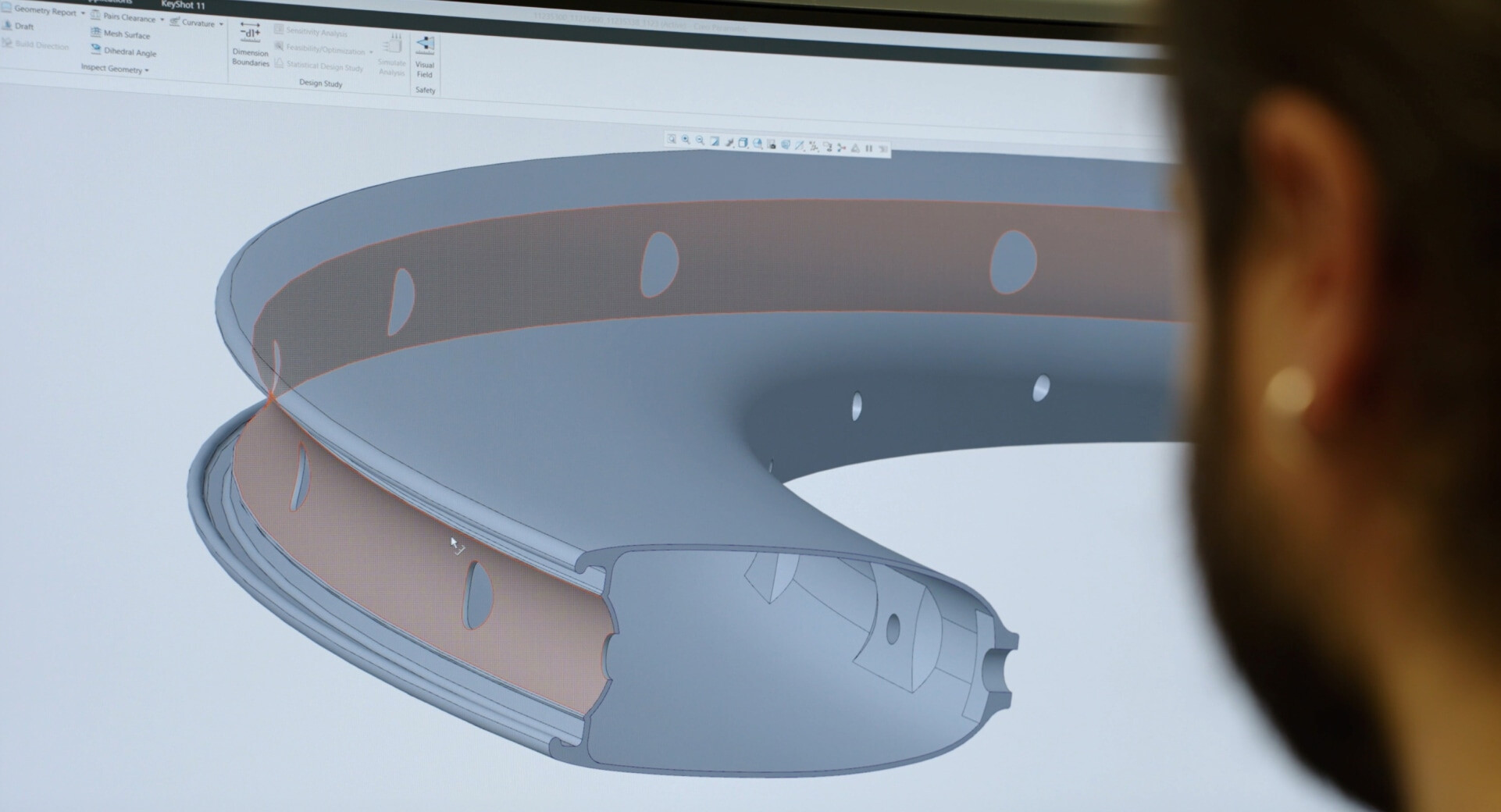

IN-HOUSE MANUFACTURING

Bringing design, engineering and production under one roof means ideas become reality without barriers. With every step under our control, from conceptualization and design of the rim to the final finish, we can ensure a level of quality and precision that no other approach can match.

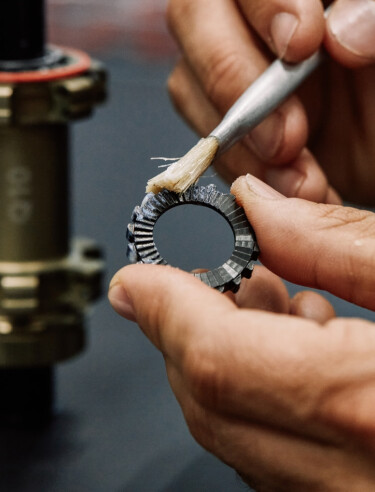

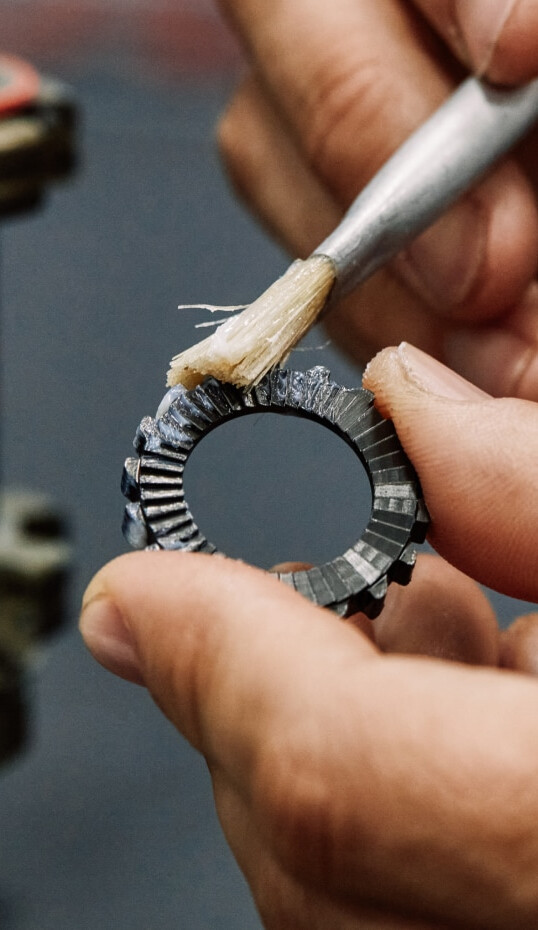

HAND-BUILT TO PERFECTION

True precision can only come from expert hands. Every part of each wheel is assembled manually, with the care and time it takes to ensure it will make the difference on the road or on the trail.

ADVANCED ENGINEERING

The building process is supported by proprietary technology and machinery that minimize errors and ensure consistency. From the exact number of nipple turns to the perfect spoke tension, every step is measured and controlled.

TESTING LAB

Our test lab is where trust is forged. Here we refine our designs and optimize configurations until the final result is simply perfect. Far beyond industry and UCI test standards, our wheels are subjected to nearly twice as many trials as conventional brands. We push them to the limit.

RESPONSIBLE MANUFACTURING

We are deeply proud to design and manufacture OQUO wheels in the Basque Country. By concentrating everything we do in one place, we can exercise greater control over our processes and ensure the quality of our wheels. We are also committed to responsible practices, using recycled and recyclable packaging and shortening our supply chain.