OQUO Q10 hub is engineered to deliver unparalleled performance, combining high-quality materials, advanced machining, and innovative design features to ensure exceptional reliability and efficiency.

AEROSPACE-GRADE ALLOY, 100% CNC MACHINED

We use aerospace-grade Aluminum 7075 T6, known for its resistance and strength. This material is harder to machine but offers superior durability compared to most steels on the market, making it ideal for demanding conditions.

The hubs are fully CNC machined, a high-precision process that allows us to eliminate excess material, ensuring superior strength while reducing weight.

7075 T6 Alloy: Aerospace-grade, CNC machined for strength and resistance.

Proven Durability: More resistant than typical aluminium, trusted in the aerospace industry.

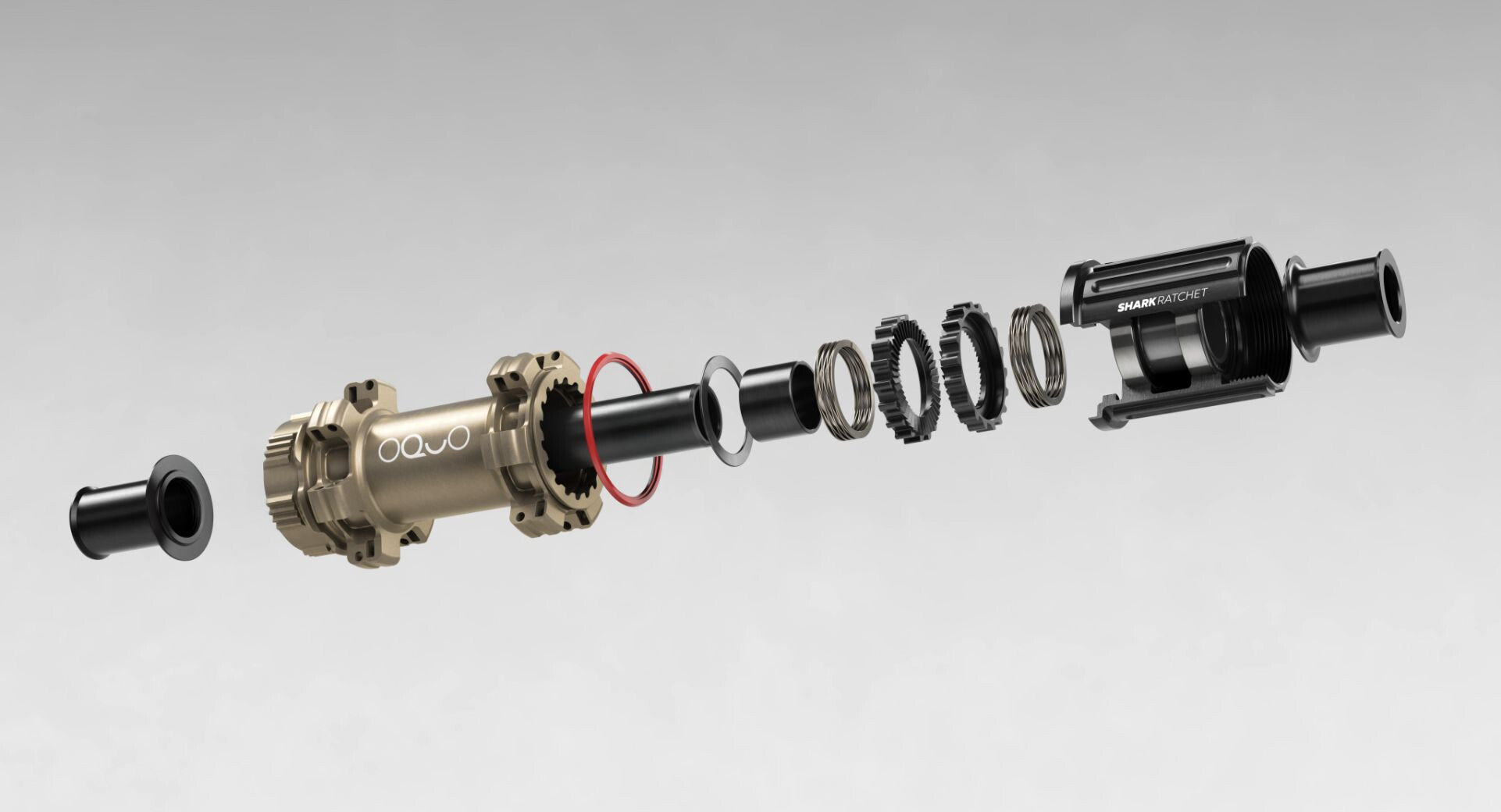

SHARKRATCHET: PERFORMANCE-DRIVEN PRECISION

The hubs feature a unique 45T design with 8º of engagement, ensuring instant power transfer. This design, combined with anti-friction ceramic treatment derived from the aerospace industry, guarantees watch-grade precision and responsiveness.

SHARKTOOTH AND CREST-TO-CREST DESIGN

The Sharktooth design is fully machined into the hub body, providing the most reliable internals on the market. The Crest-to-Crest spring design offers improved efficiency by handling axial stresses more effectively, further enhancing the hub's durability and performance.

DESIGNED FOR EASY MAINTENANCE

The hubs are designed for simple maintenance. With no threaded parts, you only need your hands to disassemble the hub and access the bearings, making it easy to service with minimal tools.

No Threaded Parts: Easy disassembly without special tools.

LOW FRICTION: CUSTOM BEARINGS AND ADVANCED SEALS

Our custom-designed bearings are engineered for low friction and exceptional durability. The stainless steel balls and optimized tracks minimize resistance, ensuring smooth operation even under high stress and extreme temperatures.

The high-efficiency connection between the hub body and the freehub minimizes friction, while our advanced sealing technology protects the internals, ensuring reliable performance in all conditions.

Custom Bearings: Designed for low friction and long-lasting performance.

Ultra-Sealed: High-efficiency seal for reduced friction and better performance.

ANTI-ROTATION, STRAIGHT PULL SPOKES SYSTEM

The Straight Pull Spokes system positions the spoke heads closer to the axis of rotation, improving power transmission and minimizing mechanical losses. This enhances overall efficiency and wheel responsiveness. Additionally, the T-shape anti-rotational spoke heads ensure consistent spoke tension, contributing to a stronger, more stable wheel.

PROVEN RELIABILITY

We push our hubs beyond industry benchmarks. Before any design earns the OQUO logo, it undergoes intense testing by our pro teams and in-house testers.

LOCAL MANUFACTURING

Fully designed and manufactured in the Basque Country, Spain. Reducing supply chains and creating local employment.